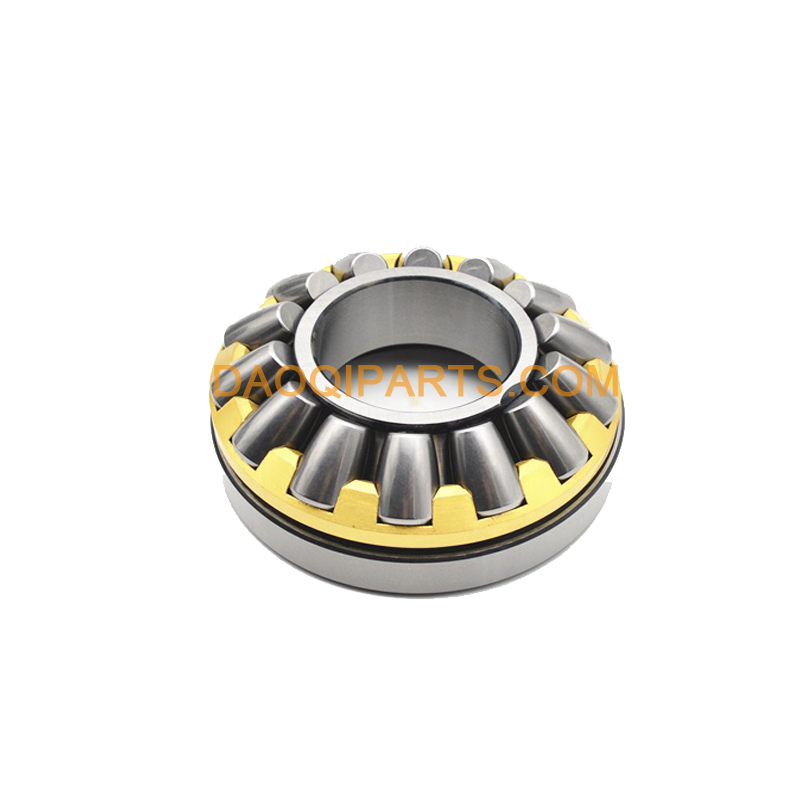

Thrust roller bearing

Classification of thrust roller bearing:

There are four types of thrust roller bearings depending on the rolling elements. Spherical roller thrust bearing, tapered thrust bearing, crosse roller bearing, and thrust needle roller bearing. Compared with spherical roller bearing, its separability is easier to install and disassemble. Compared with cylindrical roller bearings, its self-aligning performance makes it more widely used. Spherical rollers and cages are arranged obliquely. During operation, the shaft with which it is matched can be allowed to have a slight inclination, and then the axial load capacity is very large, which is the largest in the thrust bearing.

Installation Precautions of thrust roller bearing:

- The thrust bearing is a separable bearing, and the user can adjust the clearance according to their needs when installing.

- Before installing the bearing, it should be cleaned with gasoline or not and kept well lubricated.

- When the bearing is installed, it is forbidden to knock the bearing hard

- The bearing storage place should be clean and ventilated to avoid a humid environment.