Bearing removal tools are one of the most important tools in mechanical equipment maintenance. It is a special tool for disassembling ball bearings, gears, pulleys and other ring parts. It can effectively avoid damage to parts or shafts during disassembly, thereby improving work efficiency and safety. Manual hub pullers are the most popular in the service market by far.

1. The bearing removal tools are suitable for what occasions?

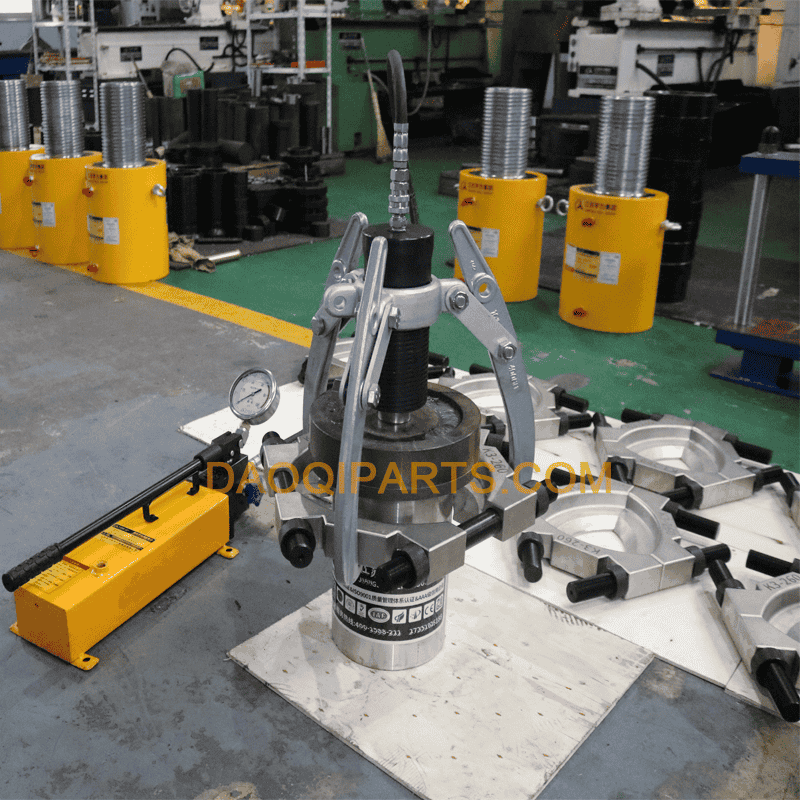

The bearing puller tool is selected according to the space and pressure of the application, and the most commonly used is the 3-jaw puller. The advantages of convenient disassembly, fast, easy and large pulling force are favored by maintenance personnel. In the fields of machinery manufacturing and maintenance, automobile maintenance, wind power industry, ship manufacturing and maintenance, construction machinery, agricultural machinery, etc., it provides a strong guarantee for the normal operation and maintenance of equipment.

2. How to choose the right pilot bearing removal tools?

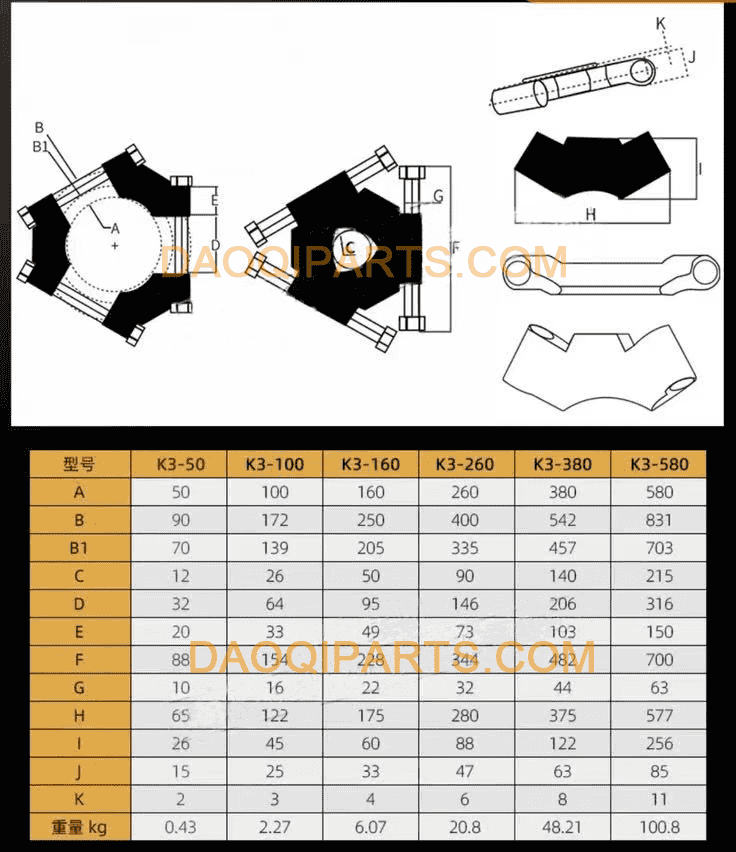

The principle of the hydraulic bearing removal tools are to hook the outer ring of the ball bearing through the claw, and push the bearing out from the sleeve by the principle of leverage. The bearing separator has different pressures such as 10T,20T,30T,50T, so the length and diameter of the puller jaws are different, and we should choose the appropriate product according to the outer diameter of the bearing to be removed. The most commonly used are 30-75mm, 75-105mm,90-140mm, 140-190mm.

3. How to avoid damage to bearings or shafts during use?

A: When pulling out the bearing, keep the screw on the puller consistent with the center of the shaft, which is the most important step.

B: When pulling the bearing, the 3-jaw should be balanced, the distance between the rod and the length of the rod should be equal, otherwise it is easy to produce skew and uneven force, and be careful not to hurt the thread of the shaft.

C: At the beginning of the pull, the movement should be slow and not too hard. In order to prevent the pull claw from falling off, the pull rod can be tied with a metal wire;

4. During the pulling process, how to prevent the bearing removal tools from sliding and causing the jaw to fall off

When the contact area between the puller jaw claw and the bearing outer ring is very small, covering a slightly larger pressure, it is so easy to cause the jaw to fall off. Then we need to be equipped with a pressure plate to increase the contact area between the puller and the bearing. The features of “knife-like” edges that can be easily placed inside the shaft, increasing the large contact area in a very limited clearance.

If you have any more questions regarding the disassembly or installation of bearings, please do not hesitate to contact us. We offer you free 7×24-hour service. Thanks for your believe.